I. Introduction

Caterpillar (CAT), a leading player in the engine industry, has its C9 and C-9 injectors attracting much attention in the market. Despite their similar names, they differ in many aspects, which have a significant impact on engine performance, efficiency, and maintenance costs. A thorough understanding of these differences is of great importance to equipment users, maintenance personnel, and practitioners in related industries. Next, we will delve into the various differences between CAT C9 and C-9 injectors.

II. Differences in Design Structure

(I) C9 Injector

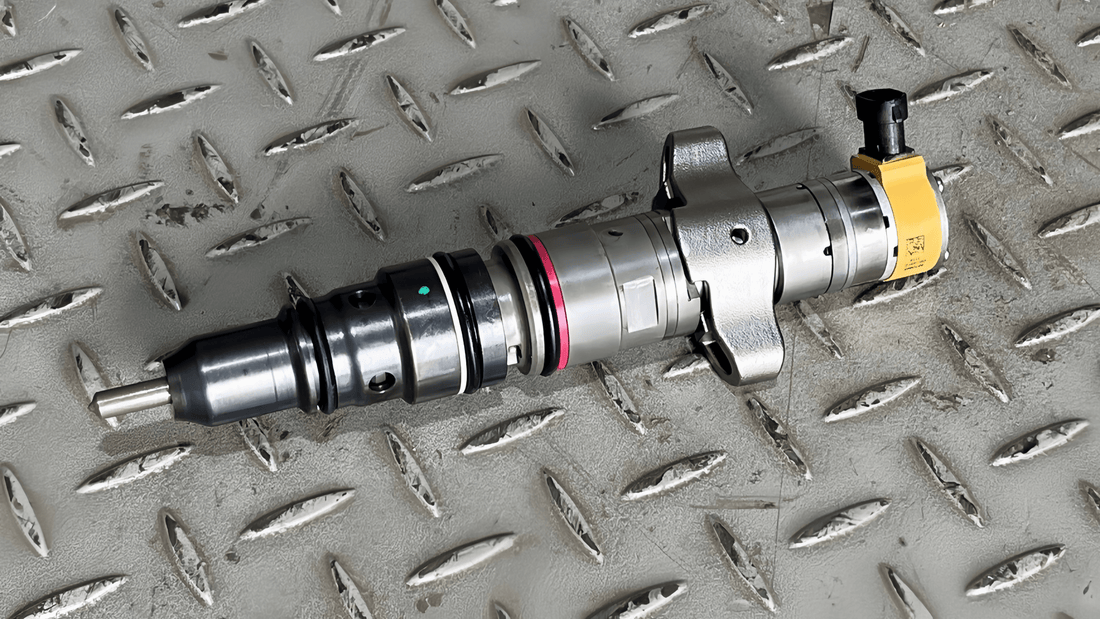

The design of the C9 injector emphasizes the stability and durability of its mechanical structure. The injector body is cast from high-strength alloy materials, which possess excellent pressure resistance and wear resistance, enabling it to operate stably for a long time in the harsh working environment inside the engine. The precision components inside, such as the fuel injector nozzle and the plunger assembly, are processed with fine craftsmanship to ensure the accuracy and consistency of fuel injection. The design of the injector nozzle's spray holes has been optimized to achieve a certain degree of preliminary fuel atomization, but its atomization effect is relatively limited. In addition, the sealing structure of the C9 injector combines traditional rubber sealing rings and metal sealing rings. This sealing method can effectively prevent fuel leakage under normal working conditions, but in extreme situations such as high temperatures and high pressures, there may be a decline in sealing performance.

(II) C-9 Injector

Compared with the C9 injector, the C-9 injector has been upgraded and improved in design. The injector body of the C-9 injector is made of more advanced lightweight alloy materials, which not only reduce the overall weight but also enhance the strength and corrosion resistance of the materials. The injector nozzle and the plunger assembly inside adopt more precise manufacturing processes. The number of spray holes in the injector nozzle has increased, the aperture has decreased, and the arrangement of the spray holes has been optimized. This enables the fuel to achieve finer atomization during the injection process, thereby improving the fuel combustion efficiency. The sealing structure of the C-9 injector adopts a multi-layer sealing design, combining high-performance sealing materials with a unique sealing shape, which can maintain good sealing performance under extreme conditions such as high temperatures and high pressures, effectively preventing fuel leakage and the intrusion of external impurities.

III. Differences in Fuel Injection Characteristics

(I) C9 Injector

The fuel injection system of the C9 injector adopts a relatively traditional mechanical control method. During the operation of the engine, the injector controls the fuel injection quantity and injection time through a mechanical linkage device according to parameters such as the engine speed and load. Although this control method has a simple structure and low cost, it has certain limitations in terms of injection accuracy and response speed. For example, when the engine operating conditions change rapidly, the C9 injector may not be able to adjust the fuel injection quantity in a timely manner, resulting in unstable engine power output and a decrease in fuel economy. In addition, the fuel injection pressure of the C9 injector is relatively low, which also affects the fuel atomization effect and combustion efficiency to a certain extent.

(II) C-9 Injector

The C-9 injector is equipped with an advanced electronically controlled fuel injection system. This system monitors the operating status of the engine in real-time through multiple sensors, such as engine speed, load, and temperature, and transmits this information to the electronic control unit (ECU). The ECU accurately calculates the required fuel injection quantity and injection time based on the received information and achieves precise fuel injection by controlling the solenoid valve of the injector. This electronic control method enables the C-9 injector to quickly and accurately respond to changes in engine operating conditions, providing more stable and efficient fuel injection. Moreover, the fuel injection pressure of the C-9 injector is relatively high, which can atomize the fuel into finer particles, promoting the full mixing of fuel and air, thus improving the combustion efficiency and reducing emissions.

IV. Differences in Compatibility and Application Scenarios

(I) C9 Injector

The C9 injector is mainly suitable for some medium and large construction machinery equipment and generator sets, etc. These devices generally have high requirements for the stability and reliability of engine power output, but relatively lower requirements for fuel economy and emission control. For example, in some mining equipment, the C9 injector can provide a stable fuel supply for the engine, ensuring the normal operation of the equipment in harsh working environments. In addition, the C9 injector has good compatibility with some older engine models. For users who need to repair and maintain old equipment, the C9 injector is a more suitable choice.

(II) C-9 Injector

The C-9 injector is more suitable for modern engines with high requirements for fuel economy and emission control. With the increasingly strict environmental protection regulations, more and more engines need to meet higher emission standards. The efficient fuel injection system of the C-9 injector can effectively reduce fuel consumption and harmful gas emissions. Therefore, it has been widely used in some new trucks, buses, and construction machinery and other equipment. In addition, the C-9 injector can also be combined with advanced engine management systems to achieve more intelligent engine control and improve the overall performance and reliability of the equipment.

V. Differences in Maintenance

(I) C9 Injector

Due to the relatively simple structure of the C9 injector, its maintenance is also relatively easy. Under normal use, regularly cleaning and inspecting the injector, and replacing worn sealing parts and filters can ensure the normal operation of the injector. However, since the fuel injection system of the C9 injector adopts a mechanical control method, some precision components such as the injector nozzle and the plunger assembly may wear out after long-term use, resulting in inaccurate fuel injection. In this case, these components need to be repaired or replaced. In addition, the sealing structure of the C9 injector is prone to aging and damage in high-temperature and high-pressure environments, so the sealing parts need to be regularly inspected and replaced to prevent fuel leakage.

(II) C-9 Injector

Although the C-9 injector has greatly improved in performance, due to its complex structure and the adoption of advanced electronic control technology, it also faces some challenges in maintenance. The electronic control unit (ECU) and sensors of the C-9 injector need to be regularly inspected and calibrated to ensure their normal operation. In addition, because the injector nozzle and the plunger assembly of the C-9 injector adopt more precise manufacturing processes, they have higher requirements for the cleanliness of the fuel. High-quality fuel needs to be used, and the fuel filter needs to be replaced regularly to prevent impurities from blocking the injector nozzle and affecting the fuel injection effect. At the same time, although the sealing structure of the C-9 injector has good sealing performance, it also needs to be inspected and maintained after long-term use to ensure the reliability of its sealing performance.

VI. Cost Differences

(I) C9 Injector

The manufacturing cost of the C9 injector is relatively low, mainly because it adopts a relatively simple design structure and traditional manufacturing processes. In the market, the price of the C9 injector is relatively affordable. For some users with limited budgets, the C9 injector is a cost-effective choice. In addition, the maintenance cost of the C9 injector is also relatively low. Due to its simple structure and low maintenance difficulty, the price of replaced parts is also relatively low. Therefore, during the entire life cycle of the equipment, the cost of using the C9 injector is relatively low.

(II) C-9 Injector

The C-9 injector has a relatively high manufacturing cost due to its advanced design structure and electronic control technology. In the market, the price of the C-9 injector is usually much higher than that of the C9 injector. In addition, the maintenance cost of the C-9 injector is also relatively high. Due to its complex structure and high maintenance difficulty, professional diagnostic equipment and tools are required for maintenance, and the price of replaced parts is also relatively high. However, the advantages of the C-9 injector in terms of fuel economy and emission control can, to a certain extent, offset its higher cost. For some users with high requirements for equipment performance and environmental protection, the C-9 injector is a worthwhile investment.

VII. Conclusion

There are obvious differences between CAT C9 and C-9 injectors in terms of design structure, fuel injection characteristics, compatibility and application scenarios, maintenance, and cost. The C9 injector, with its simple and reliable structure and low cost, is suitable for medium and large construction machinery equipment and generator sets with relatively low performance requirements and limited budgets. On the other hand, the C-9 injector, with its advanced technology and efficient fuel injection system, is more suitable for modern engines with high requirements for fuel economy and emission control. When choosing an injector, users should comprehensively consider these factors according to the needs and actual situations of their own equipment and select the most suitable injector to ensure the efficient operation of the equipment and maximize economic benefits. At the same time, with the continuous development of technology and the increasingly strict environmental protection requirements, it is believed that CAT will continue to introduce more advanced and efficient injector products, making greater contributions to the development of the engine industry.