Diesel engine injectors are crucial components in a diesel engine, responsible for delivering fuel precisely into the combustion chamber. Over time, however, they can become dirty or clogged, leading to various engine performance issues. Cleaning diesel engine injectors is an essential maintenance task that can help restore engine efficiency, improve fuel economy, and reduce emissions. In this article, we'll explore the step - by - step process of cleaning diesel engine injectors.

Why Clean Diesel Engine Injectors?

Dirty injectors can cause a range of problems. When injectors are clogged, the fuel spray pattern may be disrupted. Instead of a fine, well - distributed mist of fuel, you might get uneven or inconsistent sprays. This can lead to incomplete combustion, as the fuel isn't mixed properly with the air in the combustion chamber. Incomplete combustion, in turn, results in reduced engine power. You may notice that your vehicle has less acceleration or struggles on inclines.

Another consequence is increased fuel consumption. Since the engine isn't burning fuel efficiently, it has to work harder and use more fuel to achieve the same level of performance. Moreover, dirty injectors can contribute to higher emissions. Unburned or partially - burned fuel is released into the atmosphere, which is not only bad for the environment but can also cause your vehicle to fail emissions tests.

Tools and Materials Needed

- Cleaning Solvent: There are specialized diesel injector cleaning solvents available in the market. These solvents are designed to dissolve carbon deposits, gum, and other contaminants that accumulate in the injectors. Look for a high - quality solvent that is compatible with diesel engines.

- Injector Cleaning Kit: A comprehensive cleaning kit typically includes a cleaning fluid reservoir, hoses, fittings, and an adapter that can be connected to the injector. Some kits may also come with a pressure regulator to control the flow of the cleaning solvent.

- Socket Wrenches and Screwdrivers: You'll need these tools to remove the injectors from the engine. The specific sizes will depend on the make and model of your engine.

- Compressed Air: A source of compressed air, such as an air compressor, can be used to blow out any loose debris from the injectors after cleaning.

- Safety Gear: Always wear safety glasses and gloves when working with cleaning solvents and around the engine to protect yourself from potential hazards.

Step - by - Step Cleaning Process

Step 1: Preparation

- Safety First: Before starting any work on the engine, make sure the vehicle is parked on a level surface and the engine is cool. Disconnect the battery to prevent any electrical accidents.

- Locate the Injectors: The location of diesel engine injectors can vary depending on the engine design. In most cases, they are located on the cylinder head. Refer to your vehicle's service manual to find the exact location.

- Remove the Fuel Lines: Using the appropriate socket wrenches, carefully disconnect the fuel lines from the injectors. Be prepared for some fuel to drip out, so have a rag or a container handy to catch it.

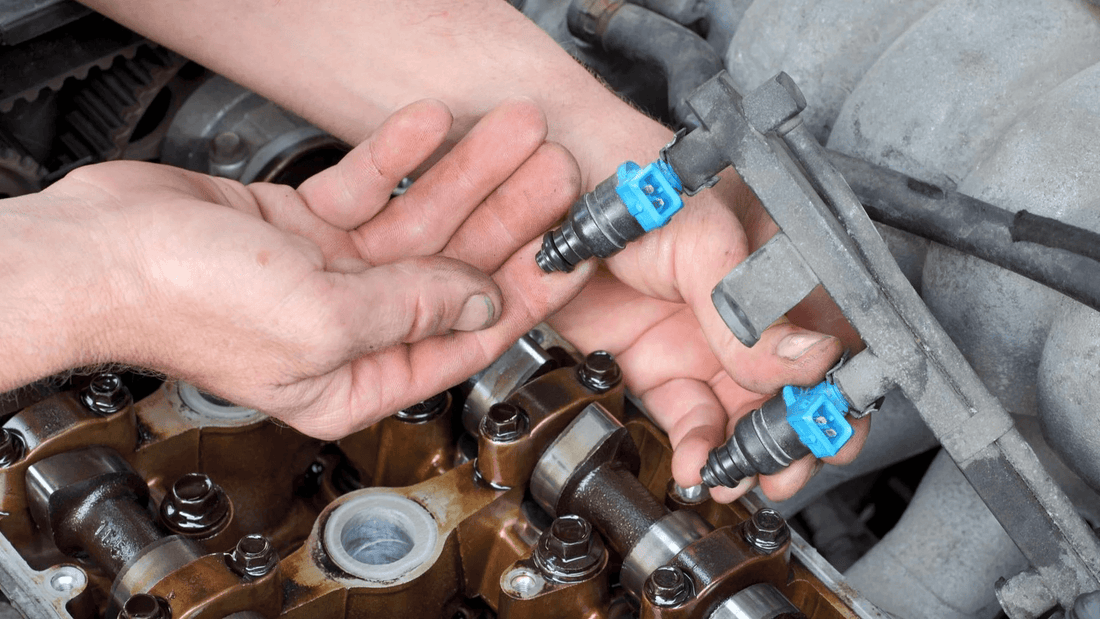

Step 2: Removing the Injectors

- Unscrew the Injector Hold - Downs: There are usually bolts or nuts that hold the injectors in place. Use the correct socket or wrench to loosen and remove these.

- Extract the Injectors: Gently pull the injectors out of the cylinder head. In some cases, they may be stuck due to carbon deposits. If so, you can use a gentle tapping motion with a soft - faced hammer to loosen them. Be careful not to damage the injector or the cylinder head.

Step 3: Cleaning the Injectors

- Soak in Cleaning Solvent: Place the removed injectors in a container filled with the diesel injector cleaning solvent. Let them soak for a few hours or as recommended by the solvent manufacturer. This soaking process helps to break down the carbon and other deposits.

- Use the Cleaning Kit: Connect the injector cleaning kit to the injector according to the kit's instructions. The cleaning fluid will be pumped through the injector at a controlled pressure. This helps to flush out any remaining debris and contaminants. You may need to repeat this process several times for each injector.

- Inspect and Scrub: After flushing with the cleaning kit, visually inspect the injectors. If there are still visible deposits, you can use a soft - bristled brush, such as a toothbrush, to gently scrub the injector nozzle and other parts. Be careful not to damage the delicate parts of the injector.

- Rinse with Compressed Air: Once the injectors are clean, use compressed air to blow out any remaining cleaning solvent and debris. Hold the injector at an angle to ensure that all the passages are thoroughly cleared.

Step 4: Reinstalling the Injectors

- Prepare the Injectors: Before reinstalling, make sure the injectors are dry. Apply a small amount of clean engine oil to the O - rings or seals on the injectors to ensure a proper seal.

- Insert the Injectors: Carefully place the injectors back into the cylinder head. Make sure they are seated properly.

- Tighten the Hold - Downs: Secure the injectors in place by tightening the bolts or nuts that you removed earlier. Use the appropriate torque settings as specified in the vehicle's service manual.

- Reconnect the Fuel Lines: Reattach the fuel lines to the injectors, making sure they are properly tightened.

Step 5: Testing the Engine

- Reconnect the Battery: After all the injectors are reinstalled and the fuel lines are connected, reconnect the vehicle's battery.

- Start the Engine: Start the engine and let it idle for a few minutes. Listen for any unusual noises. A clean set of injectors should result in a smoother - running engine with a more consistent idle.

- Check for Leaks: Inspect the fuel lines and injector connections for any signs of fuel leaks. If you notice any leaks, turn off the engine immediately and address the issue.

Maintenance Tips for Diesel Engine Injectors

- Use High - Quality Fuel: Low - quality diesel fuel can contain impurities that can quickly clog injectors. Always use fuel from a reliable source and consider using fuel additives that can help keep the injectors clean.

- Regular Inspections: Periodically inspect the fuel lines and injectors for any signs of wear, leaks, or damage. Catching problems early can prevent more serious issues down the line.

- Follow the Manufacturer's Maintenance Schedule: Different engines have different maintenance requirements. Follow the recommended service intervals for injector cleaning and other engine maintenance tasks as specified by the vehicle manufacturer.

At FuelPartsPro, we understand the importance of well - maintained diesel engine injectors. If you're in the process of cleaning your injectors and find that you need replacement parts, we've got you covered. We offer a wide range of high - quality diesel engine injectors, injector cleaning kits, and other related components. Our products are sourced from trusted manufacturers, ensuring reliability and performance. Whether you need a single injector or a complete set, our easy - to - navigate website makes it simple to find the right parts for your engine. Don't let dirty or damaged injectors compromise your engine's performance. Visit FuelPartsPro today and explore our inventory to keep your diesel engine running smoothly.