- Home

- Tipps, Neuigkeiten & Events

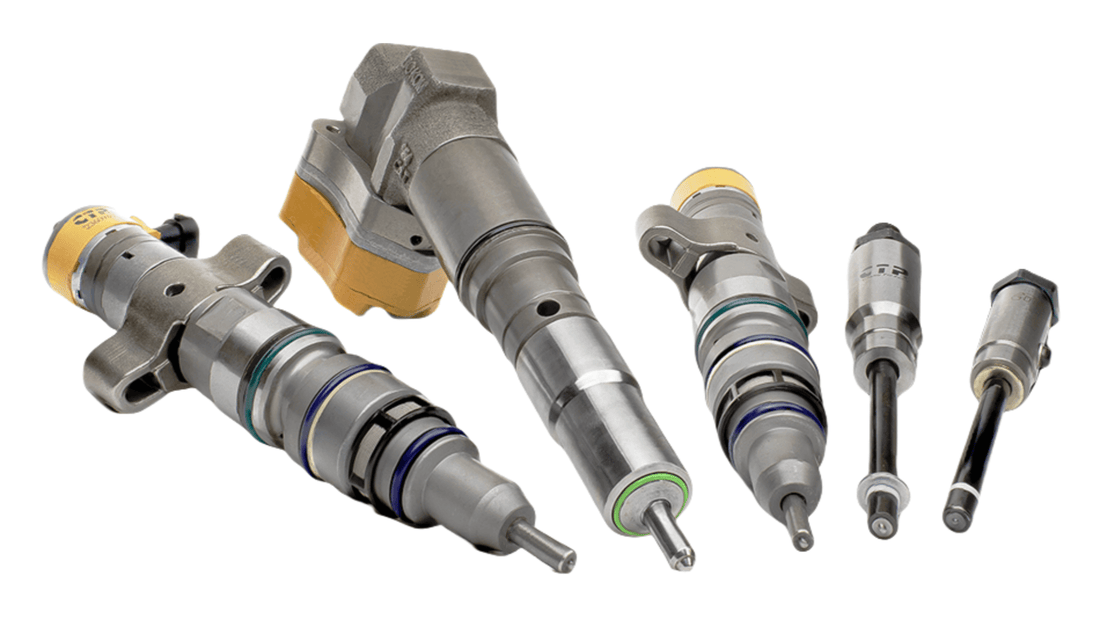

- Fault Diagnosis and Maintenance Strategies for Construction Machinery Injectors

Fault Diagnosis and Maintenance Strategies for Construction Machinery Injectors

03 March, 2025

In the field of construction machinery, the injector, as a key component of the engine's fuel injection system, directly affects the engine's power output, fuel economy, and emission levels. With the increasingly complex and high-intensity operating environments of construction machinery, injectors face numerous challenges, and the failure rate has increased accordingly. Therefore, a deep understanding of the fault diagnosis methods and maintenance strategies for injectors is of great significance for ensuring the stable operation of construction machinery and reducing maintenance costs.

Carbon Deposits Blockage: During the operation of construction machinery, due to poor fuel quality, incomplete combustion, and other reasons, carbon deposits are likely to form around the injector nozzles. Carbon deposits will gradually block the nozzles, reducing and unevening the fuel injection volume, resulting in problems such as decreased engine power, increased fuel consumption, and difficult starting. For example, in some construction site environments, the fuel storage conditions are poor, and impurities and moisture mix into the fuel, accelerating the formation of carbon deposits.

Impurity Blockage: Impurities in the fuel, such as rust and dust, may get stuck in the nozzles or needle valves when passing through the injector, hindering the normal fuel injection. In addition, the wear debris of the internal parts of the injector may also cause blockage. Take the loader as an example. Its operating environment has a large amount of dust. If the fuel filter is not maintained in a timely manner, impurities are likely to enter the injector.

Loose Needle Valve Seal: After long-term use, the needle valve and valve seat of the injector will be worn and not tightly sealed, resulting in a small amount of fuel leakage even after the injection is completed. The leaked fuel will burn prematurely in the combustion chamber, causing engine knocking, unstable idling, and other phenomena. For instance, after long-term high-load operation of excavators, the wear of the injector needle valves is relatively obvious, and the leakage problem also increases.

Fatigue of Injector Spring: The injector spring is responsible for controlling the opening and closing of the needle valve. If the spring is fatigued or damaged, the closing pressure of the needle valve will be insufficient, thus resulting in leakage. In some construction machinery operating in cold regions, due to the impact of the low-temperature environment on the performance of the spring, the injector springs are more prone to fatigue problems.

FuelParts Pro

Engineeringleiter bei einem Startup vor dem Börsengang