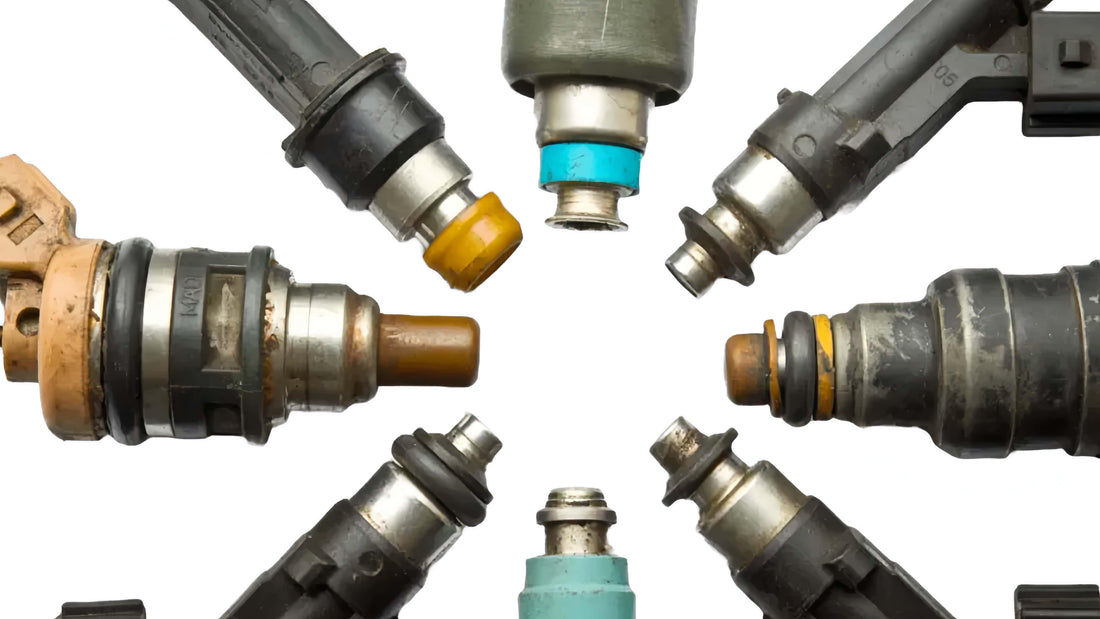

In the field of mechanical engineering, engine fuel injectors, despite their small size, have a profound impact on the performance of equipment. Previous articles have mentioned that fuel injectors play a crucial role in the engine's fuel system. This article will provide an in - depth analysis by combining practical examples and data.

Let's first look at the influence of fuel injectors on the engine's power output. Take a heavy - duty truck of a certain brand equipped with a diesel engine as an example. Under normal circumstances, with the fuel injector injecting fuel precisely, the engine can reach a maximum power of 350 horsepower. After long - term use, the injection holes of the fuel injector became blocked due to impurities in the fuel, and the fuel injection of some holes was not smooth. Power tests showed that the maximum power of the engine dropped to 300 horsepower, a power loss of 14.3%. From this data comparison, it can be seen that even a minor fault in the fuel injector can significantly weaken the engine's power, affecting the vehicle's load - carrying capacity and driving speed.

In terms of fuel economy, fuel injectors are equally important. A research team conducted tests on the same model of car. When a normal fuel injector was used, the vehicle's fuel consumption per 100 kilometers was 8 liters. When the fuel injector had a problem of excessive fuel injection, the fuel consumption per 100 kilometers increased to 9.5 liters, an increase of 18.75%. This is because excessive fuel injection prevents the fuel from burning fully, not only wasting fuel but also increasing harmful substances in the exhaust gas.

Take the case of an excavator. An excavator that had been in use for many years experienced weak digging force and a significant increase in fuel consumption during operation. After inspection, it was found that the fuel injector was worn, resulting in poor fuel atomization. After replacing the fuel injector with a new one, the digging force was significantly enhanced, and the fuel consumption decreased by approximately 15%. This shows that timely maintenance and replacement of fuel injectors can restore the equipment's performance and reduce operating costs.

From the perspective of design and technology, modern engine fuel injectors use high - pressure common rail technology, with injection pressures reaching over 2000 bar. Under such high - pressure conditions, the fuel injector can spray fuel in extremely fine particles, fully mixing with the air to improve the combustion efficiency. However, the high - pressure environment places extremely high demands on the materials and manufacturing processes of fuel injectors. High - strength and wear - resistant materials are required, and the manufacturing accuracy needs to be accurate to the micron level to ensure the long - term stable operation of the fuel injector.

In conclusion, fuel injectors are of great significance in the operation of engines. To ensure the efficient and stable operation of engines, equipment users should pay attention to the maintenance of fuel injectors, choose high - quality fuel, and regularly clean and inspect the fuel injectors. Equipment manufacturers need to continuously research and develop new technologies to improve the performance and reliability of fuel injectors to meet the increasingly stringent environmental and performance requirements.