- Home

- Tipps, Neuigkeiten & Events

- The working principle of the fuel pump

The working principle of the fuel pump

14 March, 2025

Construction machinery plays a vital role in various industries, from building infrastructure to mining operations. At the heart of these powerful machines lies a crucial component - the fuel pump. In this article, we'll delve into the world of construction machinery fuel pumps, exploring their types, functions, common issues, and maintenance tips.

The primary function of a fuel pump in construction machinery is to transfer fuel from the fuel tank to the engine's combustion chamber. It ensures a consistent and pressurized flow of fuel, which is essential for the engine to operate smoothly. Just like the heart pumps blood throughout the body, the fuel pump pumps fuel to keep the engine running.

In diesel - powered construction machinery, which is widely used due to its high torque output, the fuel pump has to work even harder. Diesel engines require fuel to be injected at high pressures into the combustion chamber for efficient combustion. The fuel pump is responsible for generating and maintaining these high pressures, typically in the range of several thousand pounds per square inch (psi).

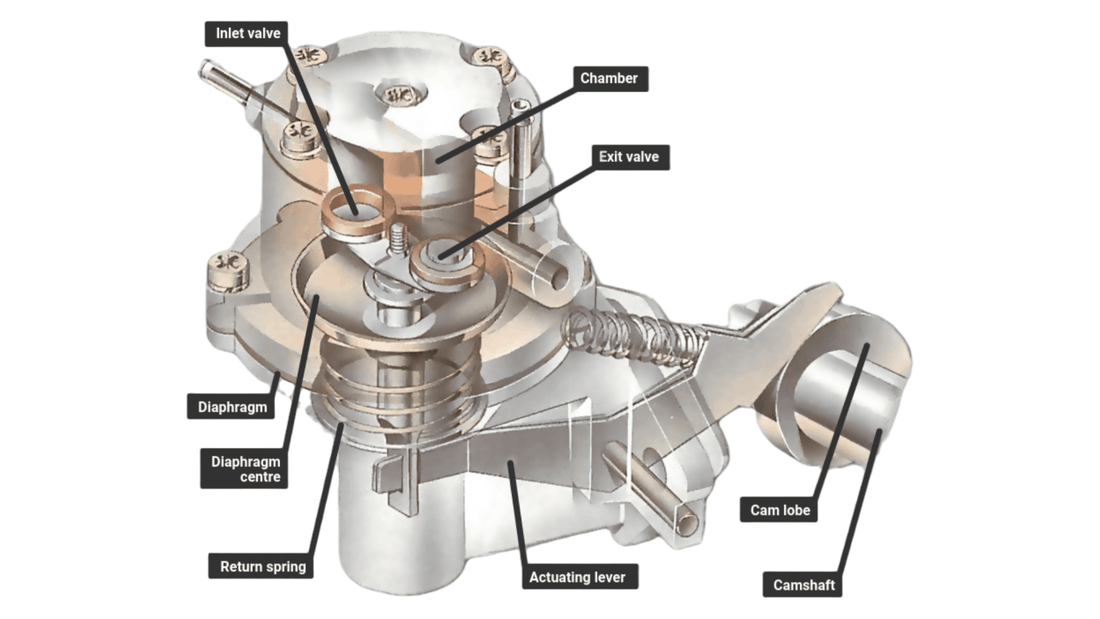

Mechanical fuel pumps are one of the oldest types used in construction machinery. These pumps are typically driven by a camshaft or an eccentric on the engine. As the engine rotates, the camshaft or eccentric activates a diaphragm or a plunger within the fuel pump. This action creates a vacuum that draws fuel from the tank and then forces it towards the engine.

Mechanical fuel pumps are relatively simple in design and are often used in older or smaller construction equipment. They are reliable for low - to - medium - pressure applications but may not be suitable for modern high - performance engines that require extremely high fuel pressures.

With the advancement of technology, electric fuel pumps have become increasingly popular in construction machinery. These pumps are powered by an electric motor, which allows for more precise control over the fuel flow and pressure. Electric fuel pumps can be mounted in various locations, such as inside the fuel tank or near the engine.

In - tank electric fuel pumps are common in many construction machines. The advantage of this design is that the fuel constantly cools the pump, extending its lifespan. Electric fuel pumps can also be controlled by the engine's electronic control unit (ECU), enabling better fuel management and improved engine performance.

High - pressure common rail (HPCR) fuel systems are a modern innovation in construction machinery. The HPCR fuel pump is a key component of this system. It pressurizes the fuel to extremely high levels, often exceeding 20,000 psi, and delivers it to a common rail. From the common rail, the fuel is distributed to individual injectors at the right time and in the right quantity for optimal combustion.

HPCR fuel pumps offer several advantages, including better fuel atomization, reduced emissions, and improved fuel efficiency. They are commonly found in large - scale construction equipment with high - power diesel engines, such as excavators, bulldozers, and large loaders.

One of the most common problems with fuel pumps is clogging. Over time, dirt, debris, and contaminants in the fuel can accumulate in the fuel pump, restricting the fuel flow. This can lead to engine misfires, reduced power, and poor fuel economy. Clogging can be caused by using low - quality fuel or a dirty fuel filter that fails to trap impurities.

The constant operation of the fuel pump can cause wear and tear on its internal components. The moving parts, such as the diaphragm in a mechanical pump or the gears in an electric pump, can become worn out over time. This can result in a loss of fuel pressure, inconsistent fuel delivery, and ultimately, engine failure if not addressed promptly.

Electric fuel pumps rely on an electrical supply to function. Issues such as a faulty wiring harness, a blown fuse, or a malfunctioning electric motor can cause the fuel pump to stop working or operate erratically. Electrical problems can be difficult to diagnose without the proper tools and knowledge.

A clean fuel filter is essential for the proper functioning of the fuel pump. It traps dirt, debris, and contaminants in the fuel, preventing them from reaching the pump. Construction machinery operators should follow the manufacturer's recommended maintenance schedule for fuel filter replacement. In general, fuel filters should be changed every few hundred hours of operation or at regular intervals specified in the equipment's manual.

Using high - quality fuel is crucial for the longevity of the fuel pump. Low - quality fuel may contain impurities that can damage the pump and other components in the fuel system. Always purchase fuel from reliable sources and consider using fuel additives that can help clean the fuel system and prevent deposits from forming.

Regular inspections of the fuel pump and the entire fuel system are necessary. Look for signs of leaks, loose connections, or abnormal noises. Check the fuel lines for any signs of wear or damage. If any issues are detected, they should be addressed immediately to prevent further damage to the fuel pump and the engine.

For complex fuel pump issues or when in doubt, it's advisable to seek professional servicing. Trained technicians have the expertise and specialized tools to diagnose and repair fuel pump problems accurately. They can also perform routine maintenance tasks, such as fuel pump calibration and pressure testing, to ensure the optimal performance of the fuel pump and the engine.

At FuelPartsPro, we understand the critical role that fuel pumps play in construction machinery. If you're facing issues with your construction equipment's fuel pump or need to replace a worn - out pump, we've got you covered. Our website, FuelPartsPro, offers a wide range of high - quality fuel pumps and related components for various construction machinery models. We source our products from trusted manufacturers, ensuring reliability and performance. Whether you need a mechanical fuel pump for an older machine or a high - pressure common rail fuel pump for a modern excavator, our easy - to - navigate website makes it simple to find the right parts. Don't let a faulty fuel pump disrupt your construction operations. Visit FuelPartsPro today and explore our inventory to keep your machinery running smoothly.

FuelParts Pro

Engineeringleiter bei einem Startup vor dem Börsengang